You don’t usually have to do that, you will even worse the situation if you ever need to extend them again (see below), even if you save the formerly removed part of the cable. You can also find designs with two 100 Ohms resistors in each wire from the strain gauge to the ADC, so it’s not about ohmic resistance.

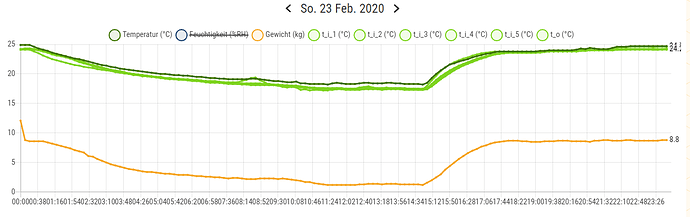

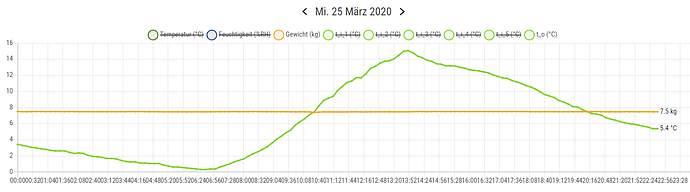

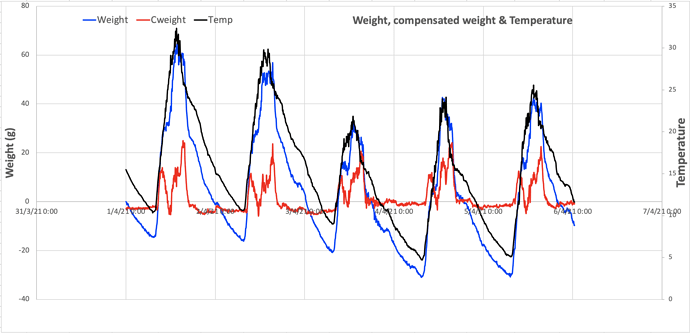

If you can ensure the weight scale body is not exposed to sunlight which excludes simple themal expansion of the strain gauge, then you still suffer this:

That’s the key point: partly. What puzzles you, remains being the Seebeck effect.

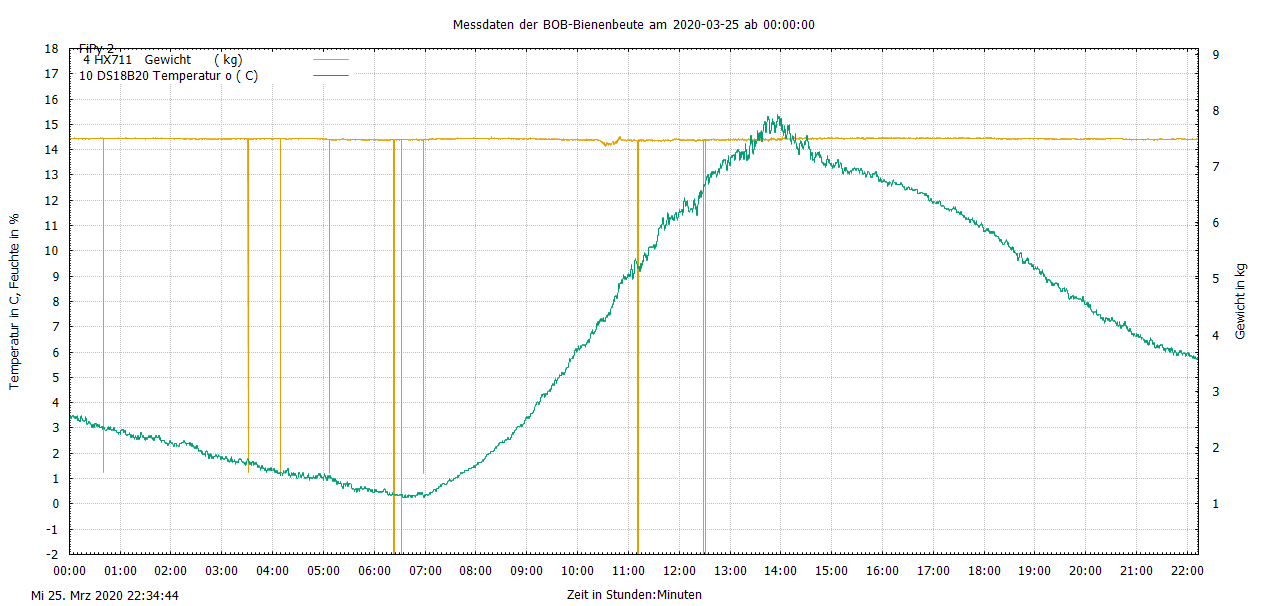

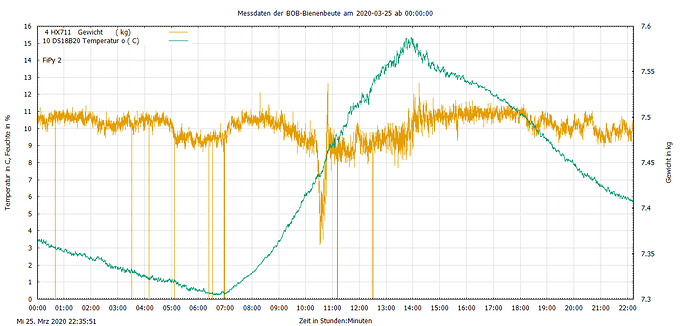

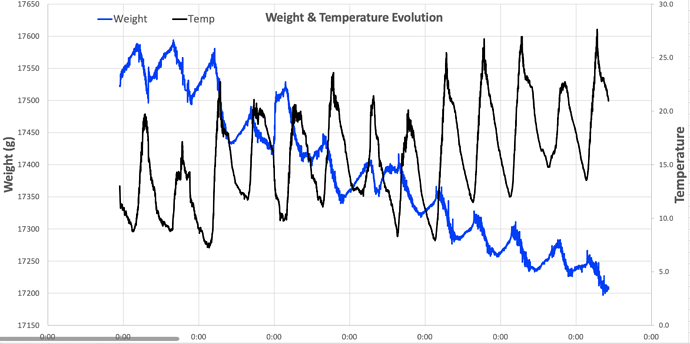

You are observing the results of a voltage introduced by wires of different materials attached to each other and exposed to a temperature difference. This difference is created when parts of your measurement chain are exposed to different temperatures than other parts - here: e.g. electronics and scale are in shadow, whereas a (unfortunately black!) cable sees light or even sun partly during the day. By thermal conduction, this energy is propagated to the junction of the mentioned metals - and injects these voltages.

Basically it then constitutes a themocouple, that kind of sensors you would use for fast temperature measurements over a wide range. Therefore this unwanted effect is called a ‘parasitic thermocouple’ and it happens on all mounting terminals or solder spots which connect the strain gauge with your ADC. The voltages introduced here are in the same magnitude like the ones you want to measure, that is why you encounter their effect.

To compensate this, it is therefore not only important to record the actual temperature when measuring a ‘reference’ weight, but to also keep any parts from strain gauge to ADC from getting warmer or colder than others:

- if your scale is centered under the hive, it (hopefully) never sees sunlight (or just solar irradiance). But if a part of the cable is exposed to sun, then Mr. Seebeck fools you

- when your sensor node has a solar cell attached to the node’s enclosure and is exposed to sun, it will always have another temperature than (some parts of) the cable and the strain gauge (even without sun), and so have its mounting terminals too - again an unwanted thermocouple.

- … (many other slacknesses which lead to not maintaining same temperature of measurement chain)

Remember that this unwanted voltage is not created along the wire, but only at different material on their contact spots. So reduce the number of materials involved along the chain, but most important: always strive for most uniform temperature.

I’m sure you now can explain this to yourself! :)

I repeat myself when saying that the Seebeck effect and its implications are widely underestimated. Please have a look at those various topics here which repeatedly cover these themes:

and watch how e.g. @thias, @zmaier, @Werner or @freedom2000 have solved this.

If you expose the mentioned metal contact spots to humidity, then you might create another source of voltage: an electrochemical cell… but thats another scope. It is understood to keep away humidity from electronics for various reasons.